As a leader in the development of high performance linear motors, LinMot have in the last few years pioneered combined Linear and Rotary motors. These provide independently controlled linear and rotary motions on one shaft with great advantages for Capping , Screwing and Assembly applications.

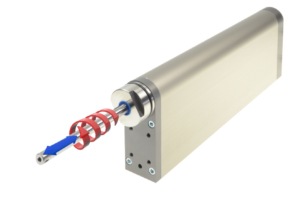

The growing PR01 Linear Rotary family of motors has now been extended to the new PR02 compact version which is available in 3 sizes, with extra features such as optional torque sensing and built-in mass compensation in the case of power-loss using their unique MagSpring technology.

Advantages

The PR02 offers many advantages such as the free parameterisation of linear and rotary movement including speed, position, acceleration and current (Torque or force) with the option of a built-in torque sensor for high-accuracy applications. This is all available in a compact design, that is easy to integrate in one physical axis, with independent programmable linear and rotary motion. The PR02 is compatible with the needs of IIoT offering Real-Time Data Evaluation and Real-Time Parameterisation.

High-speed Capping

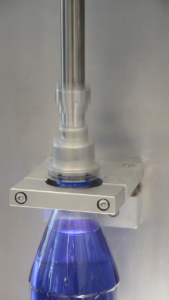

High speed Capping is a typical application example for these motors. Caps on bottles need to be applied quickly, accurately and in a repeatable manner with feedback if there are any problems.

As well as fully automating the process, the PR02 offers traceability by continuous monitoring in real time, every capped unit so that it can be traced.

A quality check can be continuously applied, knowing all process parameters on time, makes it possible to check whether the cap is applied correctly or not.

On-the-fly process optimisation is achieved by altering specific parameters, such as torque , force, speed, position etc.

Maintenance can be achieved through continuous monitoring of temperature- and current- conditions allowing prediction of oncoming failure or maintenance needs.

After picking the cap, a typical capping process involves moving the cap towards the bottle in linear position mode and then switching on-the-fly to a Constant force mode to place the cap on the bottle. The rotary motion can then turn to find the start of the thread while applying a constant linear force. Once found, the cap is rotated to a predefined closing angle with an optional torque check.

Using the PR02 eliminates the need for compensation springs and couplings and torque clutches.

Screw tightening and Assembly

The tightening of screws and assembly of products are required in almost everything that is manufactured. Now though, higher tolerances and greater feedback is needed in a modern production process.

Using the LinMot PR02, high-speed assembly can be achieved while giving feedback on screw thread quality, length and torque accuracy better than 1%.