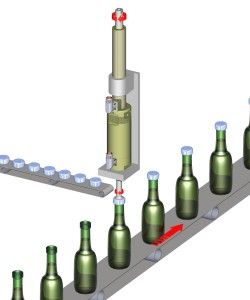

Many production line tasks, such as closure and screw driving systems, need both linear and rotary motions but the traditional ways of achieving these combined motions have considerable limitations. LinMot has launched a unique solution offering a simple implementation of these complex motions by combining a linear motor and a servomotor in a single compact assembly. Programmable press forces and torque give any combination of linear and rotary motion. In comparison with mechanical closure systems, linear-rotary motors require up to 60% less time for a closure process, which dramatically increases productivity.

Drives&Controls (July/August 2015, p77 and p78) has described the  benefits of linear-rotary motors over traditional ways of providing this motion and focussed in on the application of a PET bottle closing machine. Click on the links above to read or download the full article which describes the challenges facing machine designers and why this solution was developed in response to customer demand for a more flexible efficient solution.

benefits of linear-rotary motors over traditional ways of providing this motion and focussed in on the application of a PET bottle closing machine. Click on the links above to read or download the full article which describes the challenges facing machine designers and why this solution was developed in response to customer demand for a more flexible efficient solution.

Product Features

LinMot’s PR01 family of motors are described in more detail in our linear rotary product pages. The linear-rotary motor consists of a powerful linear motor and an attached rotary motor that can be electrically actuated independently of each other. The motors in this family provide forces up to 1024 N, a peak torque of 7.5 Nm, and speeds up to 2,000 rpm. The particularly compact and lean motors can also perform strokes up to 300 mm. Because both the linear force (press force) and the torque (tightening torque) can be controlled and monitored independently of each other, designers can adapt motion sequences to the task’s requirements profile much more easily, ensuring consistent product quality.

Application example

Carousel multi-axis closure systems, in particular, can be made compact and effective with LinMot linear-rotary motors. With this motor technology, the linear and rotary motions can be decoupled from the carousel motion for the first time. Any combination of linear and rotary motions can now be implemented. Motion profiles, speeds, turns, and press forces or tightening torques can be specified arbitrarily and independently of one another. During process monitoring, the cap position at the end of the closure process can be read in order to detect misaligned seating.

and effective with LinMot linear-rotary motors. With this motor technology, the linear and rotary motions can be decoupled from the carousel motion for the first time. Any combination of linear and rotary motions can now be implemented. Motion profiles, speeds, turns, and press forces or tightening torques can be specified arbitrarily and independently of one another. During process monitoring, the cap position at the end of the closure process can be read in order to detect misaligned seating.

These innovative multi-axis closure systems allow uncomplicated product changes at the click of a mouse. The user receives all critical parameter feedback on a continuous basis, so that the amount of downtime due to faults is significantly reduced. In comparison with mechanical closure systems, the LinMot solution with linear-rotary motors requires up to 60% less time for a closure process.

Please call us for more information or to discuss your specific requirements.