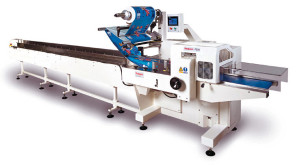

Improving the productivity of a mechanically-driven flow wrapping machine.

Why were we needed?

Our customer had a wrapping machine that was reaching limit of its capabilities. Adjusting and maintaining the current machine was time-consuming and expensive, so an electronically- controlled system was needed to improve efficiency and give the customer greater control.

What did we do?

Working alongside a major machine builder, we supplied a servo control system, complete with drives and motors. This system controls and synchronises all the mechanical movements within the machine.

How does it work?

The servo control system makes the system operations much simpler, with less wear and tear and lower maintenance costs. Product changeovers can be achieved at the push of a button and from simple menu selections. In addition, the new machine has the following features:

- the machine can incorporate a no-product-no-bag feature to save wrapping material

- the machine can also incorporate a misplaced product feature to improve machine utilisation

- plain-film bag length, relative crimp sealing speed, and phase adjustments can be adjusted while the machine is running

- the control system provides better diagnostics

- higher operating speeds are achievable

- the machines can be synchronised to upstream product handling equipment

- tension control systems can be added for handling difficult materials