With a robot that can handle tennis balls, tissue packs and champagne glasses, what more do we need for Wimbledon (apart from weather)?

By changing from pneumatic cylinders to linear motors, German machine builder Keller HCW has developed a universally deployable robot gripper with a high payload rating that can safely pick up hollow bricks, glasses, cat food packages, tiles, tissue packs and tennis balls with just the right amount of force. Benefits included improvements in precision, repeatability, maintenance and energy efficiency in addition to negating the need for multiple grippers and lost changeover time.

Keller HCW, who is one of the world’s leading manufacturers of machinery and plant for the heavy clay industry, also develops customised robotic solutions with over 500 robot installations. Robot grippers from Keller HCW (mainly pneumatic drives) have proven themselves for years in brickyards and other heavy ceramics operations. However, there were significant disadvantages of using pneumatic cylinders when different shapes and formats of bricks are run on the same line so alternative designs were investigated.

For example, they are used to grip unfired bricks (blanks) and to place them with a certain spacing that guarantees an optimal drying and firing process. The bricks are fed to the gripper on a continuously running transport belt in the form of a consolidated stack consisting of about 20 to 30 blanks. The gripper picks up the entire stack, spaces the individual bricks optimally while the robot is moving, and then places them as a group on special carriers or transport belts.

“The challenge here is that the strength of the blanks can vary, and therefore we can only apply a limited gripping force at a limited approach speed. There is also a limited time window available during which the bricks have to be picked up from the feeder belt as it continues to move,” explains Reinhold Ungruhe, the manager of Automation and Electrical Engineering at Keller HCW GmbH.

Up to now, the robot grippers that have been used for singulating bricks, as well as other handling process in the heavy ceramics industry, have mainly used pneumatic drives.

Stroke adjustments were previously limited to 10 mm by the pneumatics

Due to the limited stroke and the relatively slow speed of the pneumatic cylinders, the stroke adjustments had to be no greater than 10 mm. This is disadvantageous if different shapes and formats of bricks are run on the same line, which is increasingly the case.

In developed industrial countries today, it is typical that the few thousand bricks required for the roof of a house, including the special bricks (such as gable and ridge tiles), are produced for a specific customer in one batch on the same line.

In practice, this has meant that the brickyards have had to procure several grippers for each robot—typically 6-axis robots—and use them alternately in order to cover all of the formats and styles. With procurement costs of about 50,000 Euro per gripper, this can tie up a great deal of the company’s capital. An alternative possibility for the user is to procure just one gripper per robot and then to reconfigure it whenever a format or style change requires it. In order to minimize this time-consuming setup process for the user, Keller has come up with a hybrid gripper design. The pneumatically powered grippers can be adjusted by means of a rotary servo drive in order to be able to group more brick formats and styles using the same gripper.

Pneumatic adjustments require manual finesse

“In practice, however, it is very difficult to adjust the pneumatics,” says Reinhold Ungruhe. “Just the fact that the pneumatic actuators behave differently depending on the ambient temperature, and therefore the precise adjustment of the gripping point and the grip force is only partially possible.”

The condensate water and other contaminants in the compressed air are another factor. Pneumatic cylinders are also not maintenance-free. They need to be oiled, for example. Seals harden or leak, especially when the drive works at a high frequency, so that the entire cylinder needs to be replaced.

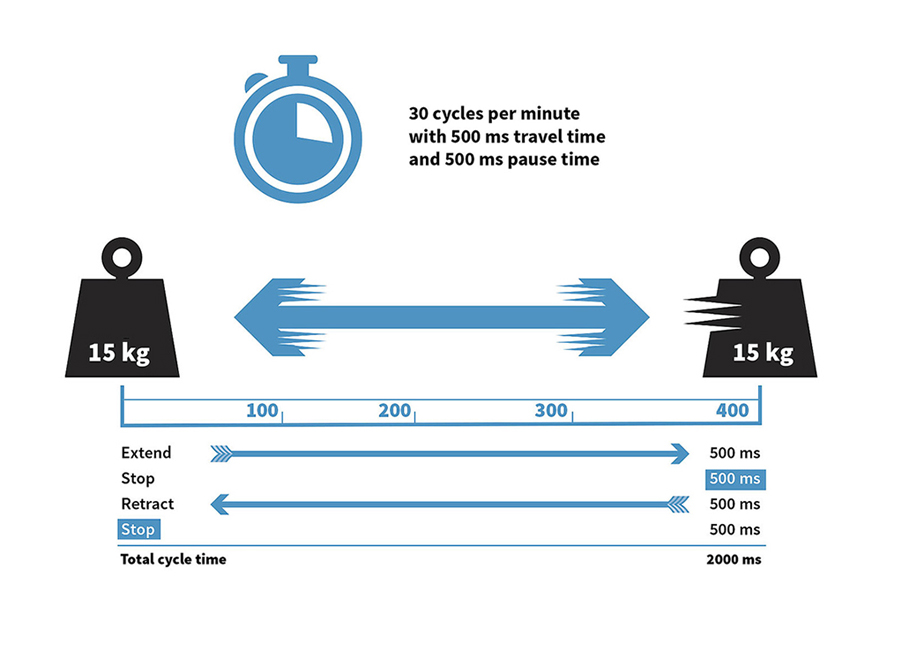

Keller therefore took a step further and developed a completely electrically powered demonstration gripper that does not have these disadvantages. Twelve linear motors, model PS01-37Sx120-HP-N from LinMot*, move the gripper jaws that are mounted directly on them. They have a maximum stroke of 120 mm, a maximum force of 122 N, and an especially compact form factor.

High dynamics and repeatability with linear motors

“Linear motors can be controlled more precisely and are more dynamically than pneumatic drives. They can also cover a much longer stroke in a short time,” says the Keller specialist for automation and electrical engineering, summarizing the advantages.

The pattern in which the bricks are placed can be entered at the system’s user interface and changed at the push of a button. No time-consuming gripper change or setup is required. Unlike with pneumatic drives, the grip force can also be controlled directly. This ability and the long stroke, combined with high dynamics, are what make this gripper so universally deployable and why it can handle sensitive products, such as glasses or cardboard packages, as safely as robust products.

The linear motors in the new gripper are actuated by 12 ProfiNet servo controllers from LinMot’s C1100 series. These have been specially designed for applications where pneumatic cylinders are replaced by linear motors. The controllers are very compact and lightweight, with a height of 146 mm, width of 26.6 mm, and depth of 106 mm.

“This is important for the payload capacity of the gripper, because we wanted to mount the controller directly on the gripper, in order to keep to a minimum the number of cables running along the robot,” explains Reinhold Ungruhe.

The disadvantage of the additional weight, however, is typically more than made up for by eliminating valve banks, mechanical components, and sensors that used to be required, as well as by the greater flexibility and repeatability of the electric drives.

“For this series, it would also make sense to use LinMot multi-axis modules or distributed motors with integrated drive electronics to further reduce the weight and space required,” adds the automation expert.

Environmentally friendly and economical

In developed countries, users also focus on another consideration of the direct electric drives: their frugal use of energy.

“More and more manufacturers of heavy ceramics products are discovering energy efficiency in their production facilities as a differentiator and image factor that drives sales,” reports Reinhold Ungruhe.

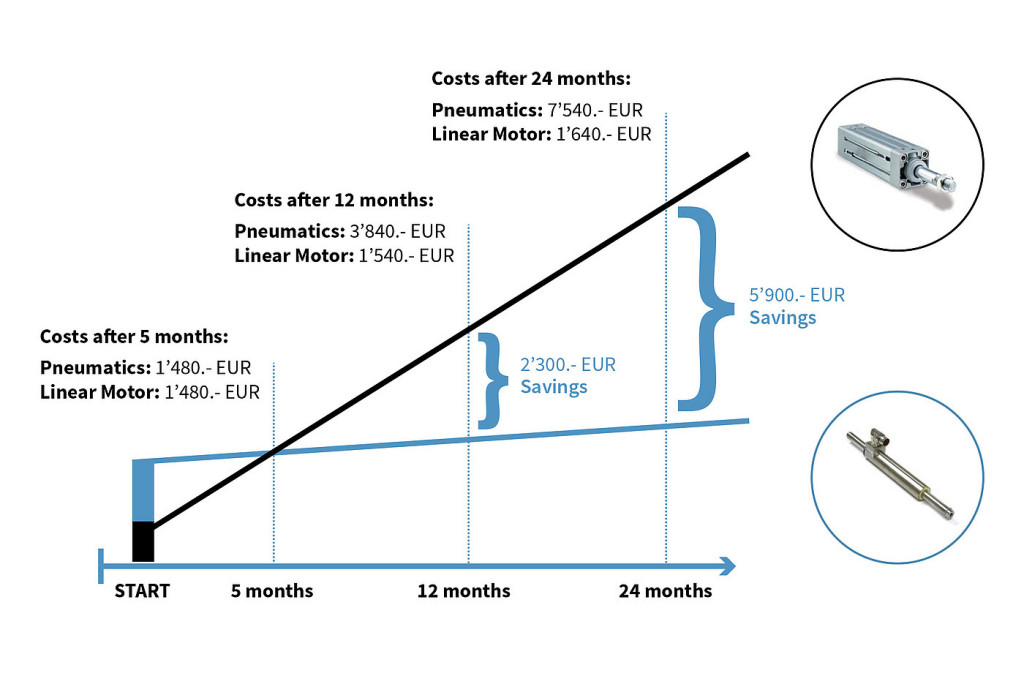

Compressed air does not fit this image, because after all it is one of the least efficient and therefore most expensive energy media. Only about 5% of the energy applied is available as useful power at the actuator. For fast cylinders, in particular, the high noise level is an indication that a lot of energy quite literally disappears into thin air. The higher procurement costs for an electric drive are quickly paid back. Even using conservative figures, its efficiency of about 97% means that it amortizes within a maximum of three years.

No wonder, then, that more and more companies are attempting to eliminate compressed air entirely in their production facilities. Keller recently built a system for packing hollow concrete blocks with rock wool with no pneumatics at all.

“The great interest that this gripper drew at the Automatica in Munich confirms our assessment that many other industries beyond the field of heavy ceramics will also follow this trend, and are looking for flexible, reliable gripping and singulating solutions based on linear motors,” says Reinhold Ungruhe, optimistically looking to the near future.

This post is taken from an article written by Franz Joachim Rossmann, technical journalist, Gauting.