There has been a “media frenzy” of articles concerning the risks and the impact of robotics as succinctly summarised by Tony Sacks in Drives and Controls’ editorial this month – A threat to humanity or an end to dull jobs. As far as industrial robots go the media seems to be interested in two main issues: whether robots can do the jobs of humans and if so what are the implications for employment. This post looks at some of the research into automation (including robotics) that has been the source for many of these stories.

Will your job become automated?

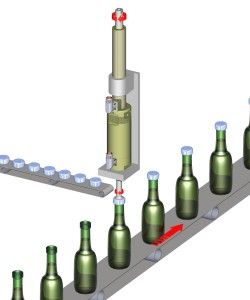

The BBC reports that about 35% of current jobs in the UK are at high risk of computerisation over the following 20 years, according to a study by researchers at Oxford University and Deloitte. On their website you can type in your job and find what the likelihood is of finding yourself replaced by a robot. Oxford University academics, Michael Osborne and Carl Frey, have calculated the probability of automation for each job based on nine key skills required to perform it. These key skills are defined as social perceptiveness, negotiation, persuasion, assisting and caring for others, originality, fine arts, finger dexterity, manual dexterity and the need to work in a cramped work space. Not being able to resist, I selected “Design and Development Engineer” to find out that the risk of automation was quite unlikely (3% probability of automation). Surprisingly, as the technology is already available from Quin Systems and others, I found out that “Packer, Bottler, Canner and Filler” had a risk of automation of “not very likely” (38% probability of automation.)

Impact on employment

Concerns have been voiced about the forecast decline in, particularly, low-paid employment and the resulting social implications. Counter arguments made by advocates of automation include:

– That without the productivity gains enabled by automation jobs will be lost to companies that embrace automation.

– To some extent automation will create higher paid and higher skilled jobs to install and manage machines. (Forrester research estimates 16% of jobs will be automated, jobs equivalent to 9% of today’s workforce will be created so leaving a net loss of 7%.)

– Completely new jobs will be created in the future which we can’t predict today.

Mark Muro and Scott Andes, in the Harvard Business Review conclude that robots seem to be improving productivity but not costing jobs. They cite the analysis offered by George Graetz and Guy Michaels of Uppsala University and the London School of Economics which finds that industrial robots have contributed to 10% of total GDP growth in the countries studied and 16% of labour productivity growth over that time period. Muro and Andes have analysed the data from this study and have found no correlation between a country’s use of robots and the percentage of manufacturing jobs lost. For example, despite the installation of far more robots between 1993 and 2007, Germany lost just 19% of its manufacturing jobs between 1996 and 2012 compared to a 33% drop in the US.

As specialists in machine automation, our take on this may well be thought of as biased so instead of wading into the argument I thought I’d think about some of the implications for manufacturers of automation equipment and robotics.

Training for engineers and designers in automation, by colleges and company certification programmes, is recognised in the industry and well respected. But what about the recognition of training for line operators primarily affected by the introduction of line automotion? Individual training is provided with the introduction of any machine. At a minimum, operators are trained how to monitor, clean, lubricate and adjust the machine and change products. In fact, Quin Systems incorporates operator training prior to installation on site as part of the acceptance process. Perhaps we could do more to ensure that the benefits of our training are understood and accessible to line operators and that the skills learnt are recognised and valued. More extensive use of remote diagnostics could be used for mentoring employees and developing skills.

Training for engineers and designers in automation, by colleges and company certification programmes, is recognised in the industry and well respected. But what about the recognition of training for line operators primarily affected by the introduction of line automotion? Individual training is provided with the introduction of any machine. At a minimum, operators are trained how to monitor, clean, lubricate and adjust the machine and change products. In fact, Quin Systems incorporates operator training prior to installation on site as part of the acceptance process. Perhaps we could do more to ensure that the benefits of our training are understood and accessible to line operators and that the skills learnt are recognised and valued. More extensive use of remote diagnostics could be used for mentoring employees and developing skills.

The Future

These researchers are pointing to the ability of automation to increase productivity and so maintain a company’s competitiveness leading to growth so lessening any impact on employment. The UK has been one of the slowest nations to adopt automation; I wonder if the obvious interest from the media will impact future uptake.