LINEAR is not just a customer magazine; it’s a vibrant blend of technology, creativity, and a genuine passion for innovation. Where else do linear motors move table football players, test hundreds of vehicle parts or ensure the health of millions of fish? In addition, you will find exciting information about sustainability, the latest drive technologies and, of course, plenty of LinMot power, all presented in engaging stories from around the whole world. Speaking of the whole world, take a look below to see which trade fairs you can visit soon to experience our new products from LINEAR.

All posts by Mike Webb

Linear motors now with force feedback

Linear motors are ideal for fast and accurate motion in a machine.

Linmot, the leading manufacturer of cylindrical linear motors, has made them even more suitable for demanding products that require exceptional cleanliness in the production environment. This has always been demanding for machine designers, but has been made much easier by using the Linmot DM01 Linear motor modules.

Linear motors are ideal for fast and accurate motion in a machine.

Linmot, the leading manufacturer of cylindrical linear motors, has made them even more suitable for demanding products that require exceptional cleanliness in the production environment. This has always been demanding for machine designers, but has been made much easier by using the Linmot DM01 Linear motor modules.

The DM01 Linear modules provide high precision positioning while supporting high loading with the following features:

- Stroke up to 575mm and peak force up to 572N

- Direct load mounting up to 30kg

- Clean Design

- No Slider lubrication is required.

- Higher stiffness / lower bending

- Load balance (MagSpring) & pneumatic holding brake option

- Can be combined to form two-axis systems

Are available certified for Clean Room Applications.

Incredibly sensitive force control

The latest option that has just become available is the addition of a force sensor combined with force control software.

This is an option that can be added to any of the DM01 modules.

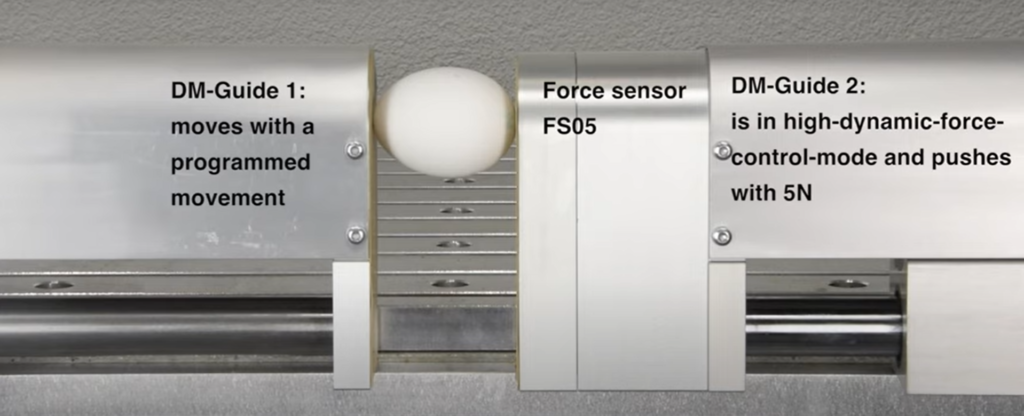

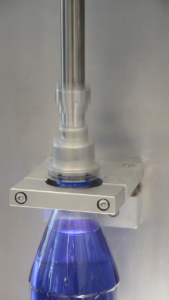

Just to demonstrate how sensitive, you can place an egg between two DM01 modules, one equipped with the new Force sensor.

One DM01 module moves with a programmed movement while the other follows while maintaining a precise 5 N force at all times to hold the egg without breaking it as shown in the picture.

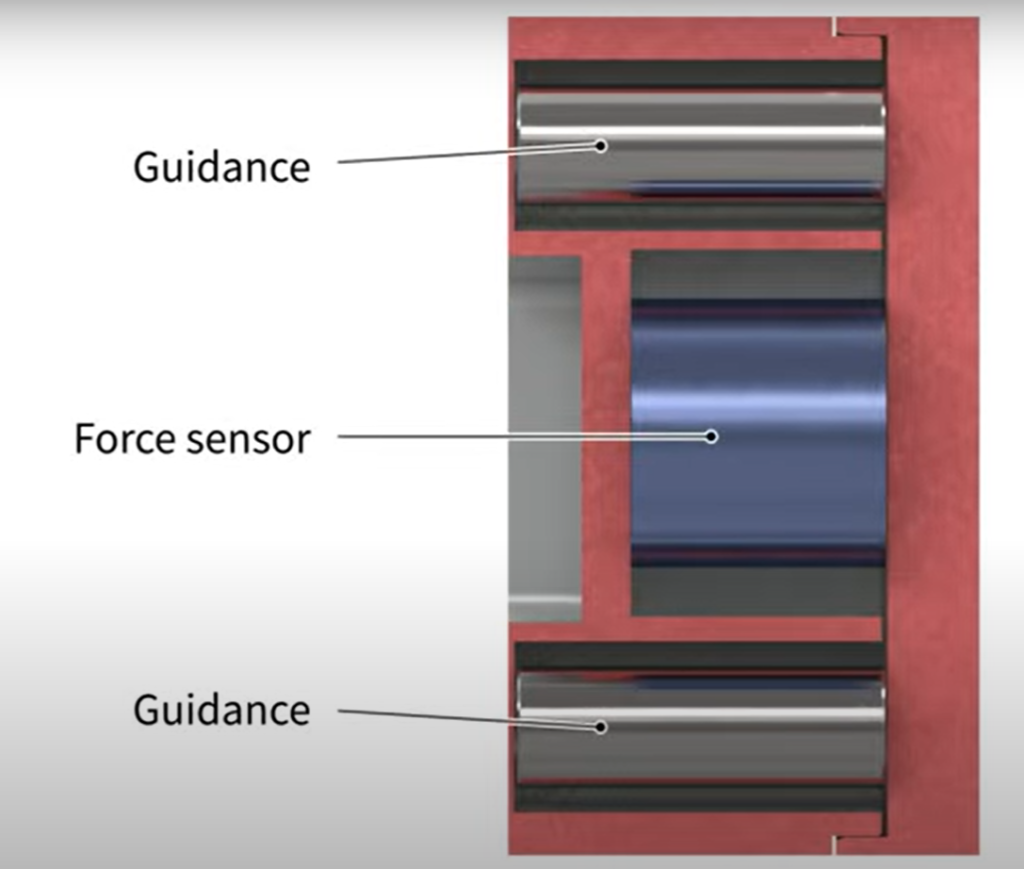

Using a regular force sensor requires precision alignment or measurement error will occur.

Linmot’s special design provides excellent measurement accuracy even with axially offset loads or with side loading from an attached load (such as a gripper for example).

Here is a section through the sensor to show how the load is guided combined with the special design of the sensor itself.

Compact Linear Rotary motor for Capping and Assembly

As a leader in the development of high performance linear motors, LinMot have in the last few years pioneered combined Linear and Rotary motors. These provide independently controlled linear and rotary motions on one shaft with great advantages for Capping , Screwing and Assembly applications.

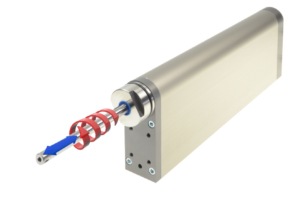

The growing PR01 Linear Rotary family of motors has now been extended to the new PR02 compact version which is available in 3 sizes, with extra features such as optional torque sensing and built-in mass compensation in the case of power-loss using their unique MagSpring technology.

Advantages

The PR02 offers many advantages such as the free parameterisation of linear and rotary movement including speed, position, acceleration and current (Torque or force) with the option of a built-in torque sensor for high-accuracy applications. This is all available in a compact design, that is easy to integrate in one physical axis, with independent programmable linear and rotary motion. The PR02 is compatible with the needs of IIoT offering Real-Time Data Evaluation and Real-Time Parameterisation.

High-speed Capping

High speed Capping is a typical application example for these motors. Caps on bottles need to be applied quickly, accurately and in a repeatable manner with feedback if there are any problems.

As well as fully automating the process, the PR02 offers traceability by continuous monitoring in real time, every capped unit so that it can be traced.

A quality check can be continuously applied, knowing all process parameters on time, makes it possible to check whether the cap is applied correctly or not.

On-the-fly process optimisation is achieved by altering specific parameters, such as torque , force, speed, position etc.

Maintenance can be achieved through continuous monitoring of temperature- and current- conditions allowing prediction of oncoming failure or maintenance needs.

After picking the cap, a typical capping process involves moving the cap towards the bottle in linear position mode and then switching on-the-fly to a Constant force mode to place the cap on the bottle. The rotary motion can then turn to find the start of the thread while applying a constant linear force. Once found, the cap is rotated to a predefined closing angle with an optional torque check.

Using the PR02 eliminates the need for compensation springs and couplings and torque clutches.

Screw tightening and Assembly

The tightening of screws and assembly of products are required in almost everything that is manufactured. Now though, higher tolerances and greater feedback is needed in a modern production process.

Using the LinMot PR02, high-speed assembly can be achieved while giving feedback on screw thread quality, length and torque accuracy better than 1%.

Technology with a heart

Linear motors mimic the heart in testing of artificial cardiovascular devices

Linear motors are used in increasingly diverse applications and much of the pioneering work is being done in our universities. This is the first in a series of posts that looks at some of the more interesting and promising applications and starts by looking at the work of Queen Mary University of London who are using linear motors to simulate the human cardiovascular system. Heart disease is the most common cause of death globally and this important research will help in the development of treatments by allowing reliable in vitro (outside the body) testing of artificial heart devices.

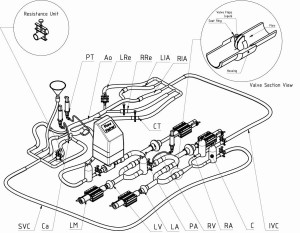

Dr Paula Ruiz-Hincapie (Queen Mary University of London), Professor Theodosios Korakianitis (Saint Louis University) and their collaborators have designed a device which simulates the human cardiovascular system and significantly improves on previous implementations so allowing reliable in vitro testing of artificial devices such as heart valves, ventricular assist devices (VADs) and mechanical circulatory support (MCS) devices. Artificial devices need to be tested in vitro prior to in vivo testing and this work improves the reliability of testing so allowing development and introduction of new medical devices.

Dr Paula Ruiz-Hincapie (Queen Mary University of London), Professor Theodosios Korakianitis (Saint Louis University) and their collaborators have designed a device which simulates the human cardiovascular system and significantly improves on previous implementations so allowing reliable in vitro testing of artificial devices such as heart valves, ventricular assist devices (VADs) and mechanical circulatory support (MCS) devices. Artificial devices need to be tested in vitro prior to in vivo testing and this work improves the reliability of testing so allowing development and introduction of new medical devices.

“This work by, funded by the NHS, has now moved from testing and proof of concept to the development of new medical devices for implantation,” adds Paula.

Unsurprisingly, simulation of the cardiovascular system is a complicated and challenging task requiring simulation of in vitro flow rates, pressures and other parameters representing normal and diseased conditions of the human cardiovascular system. Such devices are sometimes called bioreactors or ‘mock’ simulators of cardiovascular loops (SCVLs). Most SCVLs only simulate the systemic circulation (the circulation of the blood to all parts of the body except the lungs) and have other limitations such as capturing accurately the pressure waveform. Paula Ruiz, Theodosios Korakianitis and their collaborators from Shiraz University of Technology, Barts and the London NHS Trust have designed and implemented a mechanical cardiovascular system using linear motors which models all four chambers of the heart and the systemic and pulmonary circulation loops. Systemic circulation is the part of the cardiovascular system which carries oxygenated blood away from the heart to the body, and returns deoxygenated blood back to the heart. Pulmonary circulation is the portion of the cardiovascular system which carries deoxygenated blood away from the heart, to the lungs, and returns oxygenated (oxygen-rich) blood back to the heart.

Four rubber gaiters of the correct size are used to model the four chambers of the heart which are accurately activated by a separate linear motor (P01-37×120 from LinMot) to simulate the suction and ejection stages. The linear motors consist of a stator and a slider accurately controlled by an E300 LinMot controller with four channels to accurately the position of each slider according to a predefined time-varying elastance function. This allows precise emulation of the contraction and filling phases as found in the native cardiac muscle. A high speed, high performance data acquisition card from National Instrument is used to send the desired displacement trajectories from the PC to the linear motor controller and to read the measurement signals from the pressure transducers and the flow-meter to the PC. NI LabView software is used for the desired trajectory generation and monitoring tasks.

This research demonstrated that the use of linear motors for displacing individual chambers provides an accurate technique for emulating different physiological (rest and exercise) and pathological conditions of the human cardiovascular system with and without mechanical circulatory support. The experimental results demonstrated the capability of this device to replicate normal and diseased conditions. The details of the experimental simulation of the various conditions and the measurements recorded to assess the success of the simulation are published in Artificial Organs, 2013 Vol 37 No 6 p 549-560.

Paula Ruiz-Hincapie is now affiliated to the University of Hertfordshire where her work has expanded into an exciting new area. Applying her experience of simulating the cardio vascular system with linear motors, she intends to use these motors to stimulate cardiovascular cells to reproduce themselves. The intention is to populate a bespoke geometry or scaffolding that can then be transferred to a patient for replacement of a malfunctioning organ or tissue.

“The cells will be grown in the laboratory and supplied with oxygen and nutrients. Linear motors will used to apply a force profile simulating that of the cardiovascular system. We hope, one day, to use cells grown in this way to implant into diseased hearts replacing damaged tissue. To do this type of transplant today tissues would be taken from a washed and sterilised cadaver, but there is always a risk of infection or rejection by the recipient’s immune system. Our work hopes to overcome these issues by growing replacement cells from cells taken from the recipient and thereby overcoming these problems,” Paula continues.

We look forward to hearing more about this innovative work in the future and wish Paula the very best with her research.

To learn more about LinMot’s range of linear motors please take a look at our website or contact us to discuss your application.

Source: Artificial Organs 2013 Vol 37, No 6, p549-560

In Vitro Cardiovascular System Emulator (Bioreactor) for the Simulation of Normal and Diseased Conditions With and Without Mechanical Circulatory Support

*Paula Ruiz, *Mohammad Amin Rezaienia, ‡Akbar Rahideh, †Thomas R. Keeble,

†Martin T. Rothman, and §Theodosios Korakianitis

*School of Engineering and Materials Science, Queen Mary University of London; ‡Shiraz University of Technology, School of Electrical and Electronic Engineering, Shiraz, Iran; †Department of Cardiology, Barts and the London NHS Trust, London Chest Hospital, London, UK; and §Parks College of Engineering,Aviation and Technology, Saint Louis University, St. Louis, MO, USA

Linear motors help reduce the use of antibiotics in fish farms

Last month, scientists found bacteria resistant to the drug (colistin) which is used when all others drugs have failed and warn that this could mark the beginning of a post antibiotic era with people dying from untreatable infections. It is likely that resistance emerged after colistin was overused in farm animals.

Preventive medications, including antbiotics are widely used in farming and aquaculture. Norway, where fish is the third most important export has recently succeeded in nearly completely eliminating antibiotics. At their peak, in 1987, Norwegian fisheries alone used about 50 tonnes of antibiotics per year – more than were prescribed for the entire population of Norway in the same time period. Now, Norwegian fish farms are using less than 100 kg per year and 98% of all salmon farmed in the country have absolutely no exposure to antibiotics. This was made possible by vaccinating the fish.

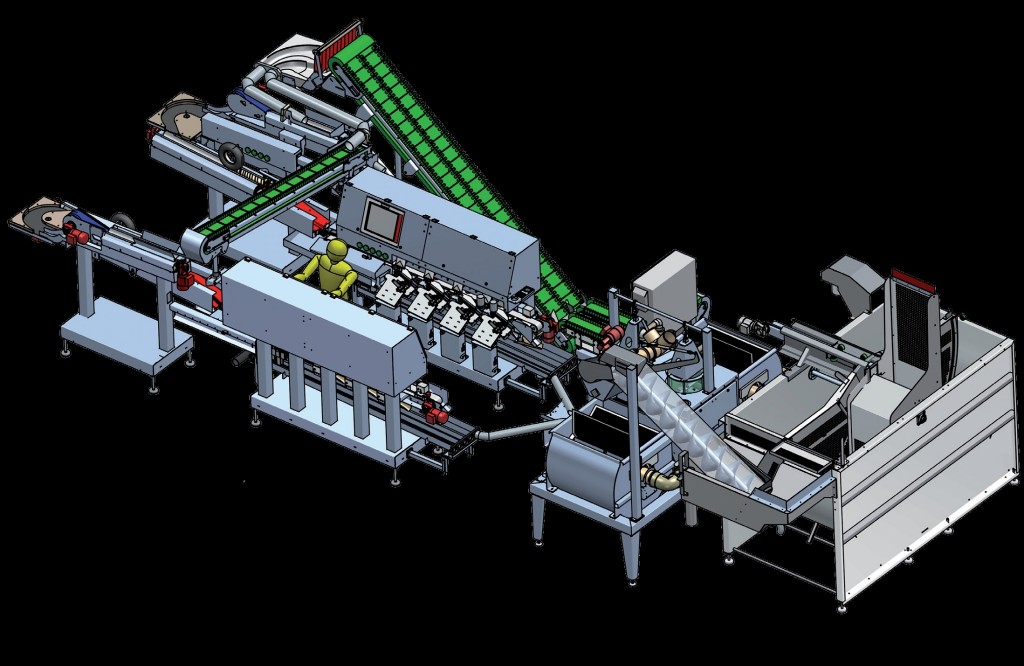

This procedure is difficult, however, because up to now each fish has had to be manually injected with the vaccine using a syringe. Considering the number of fish raised annually – 1.4 million tons of salmon in aquaculture worldwide in 2010 – this procedure had reached its limits. Drives and Controls have reported on the automation of the vaccination process by a Norwegian machine builder, Skala Maskon, whose system allows a single operator to anaesthetise, sort, singulate and vaccinate up to 20,000 fish every hour. The machine not only vaccinates many more fish but also ensures that the quality of the vaccinations is much higher than humans can achieve.

The machine consists of one or two vaccination modules, each equipped with four vaccination stations. An image processing system first measures each fish and generates information that is used to calculate the point of injection. The vaccination station is then positioned using a linear motor, making it possible to hit the optimal oinjection site for each fish with a precision of better than 98%. The length of the fish, as determined by the image procesing system, is also used to calculate the depth of the injection. A sensor on the needle monitors the injection process and the vaccine dosage for each fish. As a result, the mortality is said to be less than 0.02%.

The machine consists of one or two vaccination modules, each equipped with four vaccination stations. An image processing system first measures each fish and generates information that is used to calculate the point of injection. The vaccination station is then positioned using a linear motor, making it possible to hit the optimal oinjection site for each fish with a precision of better than 98%. The length of the fish, as determined by the image procesing system, is also used to calculate the depth of the injection. A sensor on the needle monitors the injection process and the vaccine dosage for each fish. As a result, the mortality is said to be less than 0.02%.

LinMot linear motors were chosen for their speed, precision, compact form and their ability to meet the necessary hygiene requirements. The motors are made of stainless steel and protected to IP69K, contain no gaskets and all the connections are welded. The motors are potted to prevent condensation and they have no protruding parts or gearboxes (unlike conventional servomotors).

Solution Details

The stator model, PS01-37x120F-HP-SSC-R used in the vaccination unit, has an outer diameter of 48 mm and length of 296 mm and when used together with the appropriate slider is able to apply a constant force of up to 210 N over the entire range of its stroke. A high-clearance variant, PL01-19×350/260, with a stroke of 120 mm was selected for the vaccination unit. The motor is controlled by a model E1100-VF-HC servo inverter, also from LinMot, which supports both force control and speed control and is designed for integrating the linear motors into systems with a master axis controller.

The stator model, PS01-37x120F-HP-SSC-R used in the vaccination unit, has an outer diameter of 48 mm and length of 296 mm and when used together with the appropriate slider is able to apply a constant force of up to 210 N over the entire range of its stroke. A high-clearance variant, PL01-19×350/260, with a stroke of 120 mm was selected for the vaccination unit. The motor is controlled by a model E1100-VF-HC servo inverter, also from LinMot, which supports both force control and speed control and is designed for integrating the linear motors into systems with a master axis controller.

The motor’s force or speed is set by the master position controller via a ±10V differential analogue signal. Either the internal LinMot measurement system built into the motor or a high-precision external measurement system can be used for feedback. Simple positioning controls can actuate the E1100-VF controller with stepper motor or directional pulse signals. For testing and commissioning, the VF controller can also be operated in point-to-point mode, with four freely programmable end positions.

For more information on LinMot products please visit our linear motor product pages.